Announcement

Collapse

No announcement yet.

Shrieking Gazelles

Collapse

This topic is closed.

X

X

-

Okay.

I quite like the 'original' style lettering (below) and which seems to have been painted on the tail-fin of the early Gazelles.

- - -

XB: Many thanks for your reply!

The 500 is highly responsive on the controls and is a thrill to fly, even though the controls are not powered.

Everyone I have discussed the Gazelle with speaks well of it and in my mind I imagine that her handling might fall somewhere between an Ecureuil and the 500?

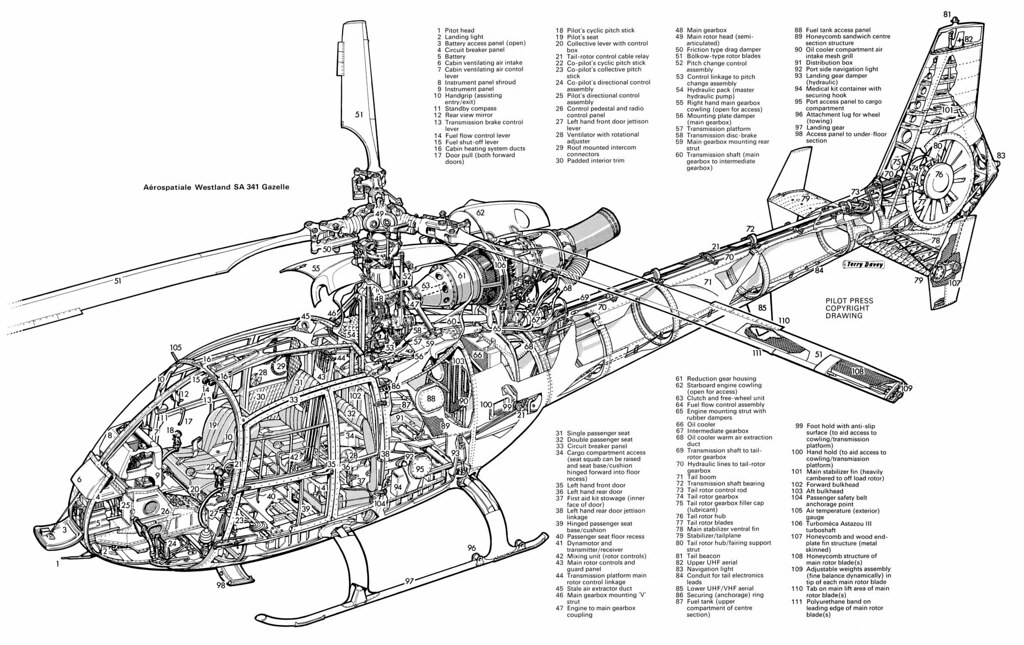

From what I understand the 341G is fitted with the Astazou IIIA which is rated at 590shp and has a basic weight of around 950kgs. The 206 in-turn is fitted with the Allison 250-C20B, rated at 420shp (if I remember correctly) and has a basic weight of around 1,100kgs. So this would be a 'nice' contrast.

What about the 342 with 870shp .. this must be 'astonishing' in terms of power reserve?

Could you explain a little about the difference in the feel of the controls with the SAS on and off please?

Comment

-

There is no difference between a 341 and 342 except some 'upgraded' components like a different style bearings and blades on the fenestron, some changes here and there. Regarding the engine, IIIA vs XIV there is indeed a power difference (590 to 870 HP) but the engine produces the same amount of power on the output shaft (limited by your torque gauge). So at sea level, there is no difference except more fuel burn. In my opinion, no use in our colder climates.

With SAS off, it also flys great but it is more stable with SAS switched ON. The 3-axis SAS is an electrical system powered by an alternator bolted onto the engine accessories sprocket. The alternator produces 120V 400Hz in 3 phases. The SAS system has 3 gyros (one for each axis), 2 magnetic brakes for the cyclic (they call it 'stick feel'), a different yaw damper and 3 electric jacks. The yaw electric jack is disabled by a BADIN switch (airspeed above 42kts I think it was) These jacks are mounted in series with the cyclic controls.

On the cyclic there are 2 buttons for the SAS; with one pressed you set the course you want to fly. When you release this button, it keeps this attitude and heading. The other button is to switch SAS off. With SAS engaged you can completely release all controls for at least 3 minutes (according to the POH). Very handy when you need to grab your maps or to take a breath :-)Last edited by xbdt; 24th June 2017, 22:21.

Comment

-

Great stuff!

This sounds very similar to the SAS fitted to the aircraft in the company for which my late godfather served as MD.

Ferranti manufactured their own SAS units in the UK and had them fitted to their 206's and Bo105's. These also had about 3 mins 'hands free' flying which, later on was increased as they sought to develop a three-axis autopilot but which was never completed. They intended to supply Westland with units for the British Forces Gazelles but I don't know if they won this contract.

My godfather used to tell me that the SAS on the JetRanger made take-off and landing easier and smoother.

Do you know which manufacturer produced the SAS unit in your Gaz?

Ferranti JetRanger depicting the 'Ferranti Stabilized' lettering which appeared beneath the Agusta-Bell badge c. 1972

Would you be able to answer some Gazelle 'myths'?

Some that I have spoken with say that to overhaul the Astazou IIIA or XIV costs in the region of €400,000. Is this in fact the case? If so, how much does it cost to buy a new one? Is the Astazou still produced?

Also, what is the time between major overhaul (the one which is supposed to cost 400k) on the Astazou?

Comment

-

The SAS manufacturer for the Gazelle is SFENA, but there is also a label ELLIOTT BROTHERS (LONDON), so I'm not sure who makes it.

The Astazou hot part is 400k EUR, cold part is also 400k EUR. A new engine is about 1M EUR. I do not think they are still making these, but spares are available. I recently found a complete Astazou IIIA with 1400 hours remaining for about 35k EUR. It is just a matter of time to find the right one for you. Military engines like IIIN2 are very very easy to find with good remaining times.

Astazou IIIA overhaul is 1750h and can be done 3x on the same core (If I remember correctly), Mil engines like IIIB, IIIN2 are 2500h between overhauls.

There are NO differences between IIIA and IIIB except the paperwork.

Comment

-

XB, thanks for this information.

Very interesting to hear about the Elliott Brothers label on your SAS unit.

Elliott Brothers were a British electronics company who, having begun with the construction of barometers and telescopes in the mid 1850's went on to supply telegraph equipment in the 1880's and 90's and eventually in 1912, a range of aeronautical equipment including gyro turn indicators and airspeed indicators.

As a point of interest, Elliott Brothers produced an aircraft tachometer which was used by Tommy Sopwith (designer of the British WW1 fighter the Sopwith Camel) when he flew the Howard Wright biplane from the Royal Aero Club's Eastchurch flying field in the UK to Beaumont in Belgium. This flight, which took place on 18th December 1910, set a new British endurance and distance record.

Elliot's were a contemporary of Ferranti Electronics and were for some time based at Rochester Airport in Kent (where I have visited many times). I am not sure whether Elliot's were involved in any joint ventures with Ferranti but that they should encounter an 'Italian influence' was part of their destiny for in 1969 they were merged with the company which had been started by the electronics and radio pioneer Guglielmo Marconi when they become Elliott-Marconi Avionics. In fact, in September 1968 English Electric, Marconi and Elliott-Automation shared a stand at the Farnborough Airshow even though at that time their merger had not been confirmed.

However, I have not been able to discover whether they actually produced the SAS unit (perhaps under licence etc.) but am inclined to think that they may have acted as distributors for SFENA.

Wow! Okay.Originally posted by xbdt View PostThe Astazou hot part is 400k EUR, cold part is also 400k EUR. A new engine is about 1M EUR.

Forgive my ignorance but what exactly do they do during overhaul? I imagine they replace all the turbine blades and perhaps also the wheels they are on (although I think they may use a one-piece blisk on the Astazou) as well as the bearings? And maybe the hot section casing? If so, that's almost a completely new hot section! And where do all these new components come from to perform the overhaul if the engine is no longer made?

People used to laugh about 'throw away' Russian turbines but, with the kind of costs you are referring to .. this doesn't sound so different! I do realise though that the Astazou is an early generation gas turbine, I suppose the only turbine produced for singles before this was the beautiful-sounding Artouste! I also recognise the 'incredible' reliability of the early Turbomeca products (astonishing really) as well as their 'self-governing' engine controls which again, were ahead of their time when compared with the alternatives of the day.

Do you know what the TBO is on the 'cool section'?

Comment

-

Well, the Elliott Brothers label is on a spare SAS computer I have; I did not actually remove the lower panel of my helicopter today to check who was the manufacturer ;-) but I suppose they were made from the same source.

I do not know what they exactly do and replace when they are overhauling the Astazou engine. Some parts are only inspected, others are replaced.

It is true that the Astazou IIIA engine is one of the most reliable engines available. The fuel distribution simply cannot fail, as long as the engine receives fuel - it will run. The governor works on its own oil pressure. No electrical signals are needed.

Since their production in '70s there is simply NO Advisory or Mandatory bulletin for this engine. This is very very rare if not exceptional! Look at the engines they are making today (40 to 45 years later...). If you take Allison for example, you'll have to do 20 mandatories before you are allowed to keep it in the air!

I do have the complete spare part, IPC and maintenance manual for the Astazou series engines, but only minor fixes or repairs could be done by A&P. I think there are only 3 facilities in the world authorised by Turbomeca to do the overhauls. The cheapest one is in Serbia.

Comment

-

Grazie XB! Very interesting.

Zis: Now that XB is aboard I've been looking for some Belgian Gazelle history but .. have had very little success. Do you have any info?

Sabena used to operate Alouette II's in the 50's and 60's and there was at least one which was involved in Medevac/Air Ambulance operations. Whether this led into what became Heli-Samu I do not know but I recall that Samu in France had a Gaz.

Touraine Helicoptere SA341G F-GEHA (cn 1064) flying as 'SAMU 37' as seen at St. Symphorien Airport in France on 6th October 1989

Comment

-

I do not know of any Gazelle ever registered in Belgium.

Sabena had lots of S55, S58.

Belgian Army had Alouette II and Marines are still using Alouette III.

List of Sabena helicopters

List of Belgian Army Alouettes

Now the Belgian army has a lot of A109 and the new NH90 (7 units) are expected soon.

Comment

-

Well done Zis! I think this is probably the extent of Gazelle involvement; those either temporarily resident or passing through or .. as with XB .. resident but wearing a non-Belgian registration.

Curious though. You would have thought that being a neighbour with France that at least one or two Gaz's might have made it onto the books!

Some Gazelle mania .. from Iraq!

Comment

-

Some nice portfolio pictures here: http://www.helico-fascination.com/re...xcellence.html

René MOUILLE is the main engineer who developed Alouette II, III, Gazelle and Dauphin. He also developed the first Fenestron (on Gazelle of course), Sphériflex, Starflex, NAT (Gazelle) rotorhead .. and had more than 100 patents filed to his name.

Comment

-

Yes indeed.Originally posted by xbdt View PostSabena had lots of S55 and S58.

Here is a clip from the opening of Brussels Heliport in 1953 where a Sabena S55 was in attendance:

Belgian connections ..

The heliport was opened by Baron Frédéric Joseph Vandemeulebroek who was Burgomaster of Brussels at the time. The video clip also shows Peter Townsend attending the opening and which, on the surface, may seem insignificant. He was in fact the air attaché to Begium from 1953-56 (and in which capacity he doubtless attended the opening) but .. if you had been forced to do your schooling from the UK then you might know that Peter Townsend was also a distinguished RAF fighter pilot.

to do your schooling from the UK then you might know that Peter Townsend was also a distinguished RAF fighter pilot.

RAF

Peter Townsend joined the Royal Air Force in 1933, and trained at Cranwell. He served in Training Command and as a flying instructor at RAF Montrose. He was stationed at RAF Tangmere in 1937 and was a member of No. 43 Squadron RAF. The first enemy aircraft to crash on English soil during World War II fell victim to fighters from Acklington on 3 February 1940 when three Hurricanes of ‘B’ flight, 43 Squadron, shot down a Heinkel 111 of 4./KG26 near Whitby. The pilots were F/L Townsend, F/O ‘Tiger’ Folkes and Sgt. James Hallowes.

By May 1940, Townsend was one of the most capable squadron leaders of the Battle of Britain, serving throughout the battle as CO of No. 85 Squadron RAF, flying Hawker Hurricanes.

Personal life

Group Captain Townsend was known for his romance with Britain's Princess Margaret. He had met the Princess in his role as an equerry to her father, King George VI. Despite his distinguished career, in the social atmosphere of the time, when divorced people suffered severe disapproval and could not remarry in the Church of England, Townsend had no realistic chance of marriage with the princess. Their relationship caused enormous controversy around 1953. The Princess eventually renounced Townsend, who was sent to take up a post at the British Embassy in Belgium.

Belgian connections

Townsend eventually married a Belgian woman, Marie-Luce Jamagne in 1959 .. and one of his sons, Hugo, married Yolande, Princess of Ligne of Belgium.

Townsend's other son, Giles, is President of the Cambridge Bomber and Fighter Society who are currently restoring a Mk I Hawker Hurricane of No. 85 Squadron and a Hawker Fury of No. 43 Squadron.

Squadron Leader Peter Townsend DSO, DFC, chatting with ground crew who are seated on his Hawker Hurricane at Wick in Scotland

Comment

-

Jack stall occurs when the manoeuvres are so hard that one or more of the 3 hydraulic actuators (jacks) moving the swash plate simply cannot handle the forces.

This normally results in uncontrolled pitch and a roll to the right. It is not a 'problem' related to the Gazelle only. Simply ease on the controls and everything will be back to normal.

If you fly a Gazelle according to the POH, you'll never be in a jack stall situation.

My instructor told me that a jack stall might not be demonstrated in flight as it stresses the actuators a lot and it is not allowed more than once a year or so. One day later, my examiner induced a jack stall in flight.

Comment

-

Yes I saw this footage and I think it might be my current helicopter.

Ground resonance occurs only with 3 or more bladed helicopters. It is an imbalance in the rotor; imagine a 3 blade helicopter where each blade should be 120° from each other. Mostly induced after a not so smooth landing, the forces applied while landing are transmitted onto the rotor and a blade imbalance can result. They are not 120° from each other anymore but maybe 110-110-140, this situation is only getting worse if the pilot stays onto the ground. Immediate action is to go into hover again.

Ground resonance can also occur even when the helicopter is already some time onto the ground after a smooth landing. A very little imbalance in a certain component can shake more and more (resonance) and shake the helicopter apart.

The gazelle has 2 different skid systems: rigid landing gear and flexible gear.

The rigid gear has 2 dampers on the sides of the rear landing brace and a lever in the cabin. The lever is operated by the pilot. This lever locks the flexible plate of the MGB for landing and unlocks it for flight.

The flexible gear has no dampers or levers, but the rear landing gear is hinged at the middle of the rear landing gear brace (attachment is in the luggage compartment). Also the front gear brace is hinged in both directions.

Most of the early Gazelles have been converted to the flexible gear, just because some pilots forget to operate the lever and induce dangerous situations like in the McGyver footage.

Comment

-

No, it's N341AH c/n 1032 on the footage. The same machine was "acting" in Flood (1976), The Gauntlet (1977) and The Cat From Outer Space (1978) moviesOriginally posted by xbdt View Post... I think it might be my current helicopter.

Thanks for your kind explanations ragarding Jack stall and GR phenomenons on Gazelles!

Comment

-

Here's what I have on the service history of your Gazelle:

SA.341G c/n 1042 produced in 1973 and delivered as N65146 to Vought Helicopter Co.

Then:- 1973 re-registered as CF-BBN to Ed Tercier

- 1976 re-registered as C-GDUG to Tercier Motors Ltd

- 1978 to Great Lakes Helicopters

- 1984 to Buffalo Airways Ltd

- 1985 to Northland Helicopters Alberta Ltd

- 1988 to Rotor Breeze Aviation Ltd

- 1990 to Tercier Motors Ltd

- 2011 re-registered as N341AS to Avia Export Llc

- 2013 to Southern Aircraft Consulting Inc. Trustee (delivered at Antwerp Harbour on 25/5/13 on board "APL Egypt" ship arriving from Newark/Maher).

Comment

-

Interesting stuff!

Ed Tercier obviously missed his Gaz though. He seems to have bought it from Vought, owned it for 5 years .. sold it .. then bought it back in 1990 and owned it for a further 20 years.

ps: I thought the bottom half of the Gaz door (such as on the 'old' birds) was made from metal panels?

Comment

-

According to the IPC, all door versions should be plexiglass, except for the rear doors and maybe the first 2 or 3 prototype gazelles.

Also the roof is divided in 3 parts. Center is aluminium. Left and right parts are plexi from front to rear. These are painted sometimes 1/3 from back (mil versions) and 2/3 from back for civ versions.

Comment

-

Regarding the history, c/n 1042 was made in Marignane and exported to Vought Helicopters (now Eurocopter USA) in 1973. They used it as a demo ship, added the SAS system to it (this system came out in 1975) and sold it to Ed Tercier in 1976. It stayed in his hangar from 1976 to 2006. He had it for 30 years.

I bought it last year from a guy who bought it from Ed. I have lots of pictures from when he bought it from Ed in Alberta.

It then was cleaned and repainted inside, all instruments overhauled etc... but due to lack of time and money he was forced to sell it. This is when I came in :-)

I saw the ad on Internet, jumped into a plane to Newark, dismantled the rotor head, fitted it into a high cube container. 10 days later it arrived in Antwerp. 3 days later the truck with the container and its contents stopped at my door.

Good but stressful moments!

Comment

Comment